Fountain Pen Ink Properties

Trying to find the right ink for certain ink and paper combo may be a challenging task. This post will give a rough guideline on different properties of fountain pen ink and how they work with nib and paper.

First and foremost, it is HIGHLY recommended to stick to fountain pen ink when using fountain pens.

Dipping pen ink often contains Arabic gum or other forms of thickener to make the ink flow slower. It helps to keep the ink flow slower in dip pens but detrimental to the fountain pen's feed system.

Fountain pen ink relies on capillary action to function and composed of mostly water, dye, some surfactant plus herbicide. Some specialized ink has micro sparkles, pigment, and other binding agents in them, however, at the end of the day, fountain pen inks are mostly heavily dyed water.

Common properties/description of fountain pen inks are listed below.

Wetness/Flow:

Wet ink will easily flow from one surface to another. Dry ink is the opposite.

Capillary action is the main contributing factor to the wetness of fountain pen ink. In general, wetter ink has less surface tension and stronger capillary action.

Wet ink can help a fountain pen with dry start issues caused by a slight baby’s bottom or less than the ideal spacing between nib and feed. The weaker surface tension and stronger capillary action allow ink to reach out further than usual and have an easier time forming a contact between nib, ink, and paper.

Wet ink comes with its own set of issues as well.

As ink gets wetter, more ink will be laid down on the paper, causing longer dry time.

Wetter ink also means that the ink will travel more easily between paper’s fiber, increases the chance of having more bleed through and feathering.

It also increases the chance of ink bleeding into the nib’s design/surface, also commonly known as nib creep. It’s a cosmetic issue that may or may not bother some users.

Manufacturers tend to formulate their ink to match their fountain pen. In general, European fountain pens come with higher flow tuned nib and feed, while providing dryer ink.

Asian fountain pen tends to have more moderate to dry flow, but their manufacturers tend to make ink with moderate or wet inks to compensate. However, this is not definite, especially considering brands like Sailor released hundreds of inks with different colors, formulas, and purposes to choose from.

We can make a dry ink wetter by adding a very small amount of surfactant or flow enhancer additive. The most common house item suggested on the internet would be dish soap. However, dish soap also tends to take lubricants away from rubber/silicon seals, making piston/vacuum fillers harder to operate after a few refills.

I have better performance using actual flow enhancer additives. One drop of Organic Studio Flo-Plus into 5 ml of ink will turn dry inks into inks with a very generous flow. The Kodac Photo Flo works as well, but without the antifungal property.

A little bit of these enhancers goes a long way. Use too much of it added, your pen will turn into a messy firehose.

Nib Creep, You can see ink traveled from the slit to other portion of the nib via groove formed by the stamped pattern.

Pigmented:

These are ink that used tiny pigment particles instead of dye for their color. Pigmented inks are typically water and solvent-resistant, modern pigment ink for fountain pens has the pigment ground in much smaller particles, so pen/feed clogging isn't much of an issue compare to older pigment inks.

However, most modern pigmented inks are relatively dry inks, pens with moderate to high flow are recommended to be used with pigmented inks.

Bleeding/feathering & show through:

Bleeding, feathering happens when the ink decided to travel between the fine fibers of the paper and not stay put at where you originally laid down the ink.

Show through is being able to see ink written on the other side of the page, whether due to bleeding/feathering or just thin/transparent paper.

In general, coated papers are better against bleeding/feathering.

Clairefontaine Triomphe, Rhodia’s coated paper are good paper against feathering. Due to their typical thickness (80/90 gsm), they are also fairly good against show through as well.

Tomoe River Paper, both 52 gsm, and 68 gsm are even more resistant bleeding/feathering. However, since they are fairly thin and the paper is somewhat transparent, it has a considerable amount of show through.

Please note that the more resistant to feathering, the less absorbent the paper will increase dry time significantly.

Personally, I found the Midori paper to be a good balance between bleed through resistance and dry time, a great everyday paper.

Some inks are specifically formulated against feathering as well, (some od Noodler’s line of inks)

Also, pigmented inks have less tendency to feather, due to the nature of the ink.

In general, fountain pen with less ink output, aka finger nib and dryer flows will have less issue with feathering than thicker/wetter nibs.

Different degree of Bleed/show through caused by different ink formula.

Dry time:

Many elements affect ink’s dry time.

The absorbance of the paper, the amount of ink laid down, saturation of the ink, other additives, etc. all changes the time requires ink to dry.

In general, ink will dry faster if the paper is more absorbent, and paper with a thin, smooth coating on them will cause the ink to dry slower.

Inks are composed mostly by water, dye, and sometimes, pigment.

More saturated ink tends to dry slower. In some extreme cases, when ink is way too saturated (some of the extremely sheening inks) the ink may still smear when rubbed even after extended dry time.

This is due to dye not absorbed/seep into the paper and became thick dye cake resting on the paper instead.

Ink with other additives, for example, lubricated inks may take longer to dry.

Lubricated:

Wet ink typically makes a nib write smoother on most surfaces, this doesn't mean the ink is lubricated.

A lubricated ink means some form of lubricant is added to the ink to help the pen to write smoother under similar flow, or to help refill mechanism operate smoother.

For most fountain pens, lubricated ink not really needed. However, if a user liked to clean and flush their pen with soapy water, then there is a chance he/she may accidentally wash out the lubricant originally applied to the piston/vacuum mechanisms and not function as smoothly as it should.

If taking apart the pen to reapply lubricating grease is too difficult or too risky, then a lubricated ink may help to make the piston/vacuum mechanism to function better.

The most common lubricated ink are ones with eel or cuddle fish additive added to the ink.

Water-resistant:

The ability for the ink to not be washed away by water after it's properly dried.

Most modern fountain pen inks are not water-resistant. The exception would be pigmented ink and iron gall ink. Both of these ink carries tiny particles that get trapped between paper's fiber, allowing a good portion of the ink to stay in place even when the paper is drenched in water. Noodlers also make specially formulated ink that the dye binds to the cellulose in paper fiber so it won't be washed away by water after drying.

Left: Mostly Dry ink. Right: Placed in water for about 30 seconds.

Shading:

We are finally starting to get to the fun part, shading describes the ability of the ink to show a different gradient of color based on the amount of ink being laid down.

A good shading ink is typically lighter in color and requires a wet, juicy, wider nib to work well.

Sheening:

This is an interesting property of fountain pen inks.

An ink sheens not because of additives, but due to the physical structure of dried dyes.

When a large amount of ink dries on top of a piece of paper, dyes/pigment is left behind. Depending on the dye used, the structure form by dried dyes may absorb and reflect different color than the original color of the ink.

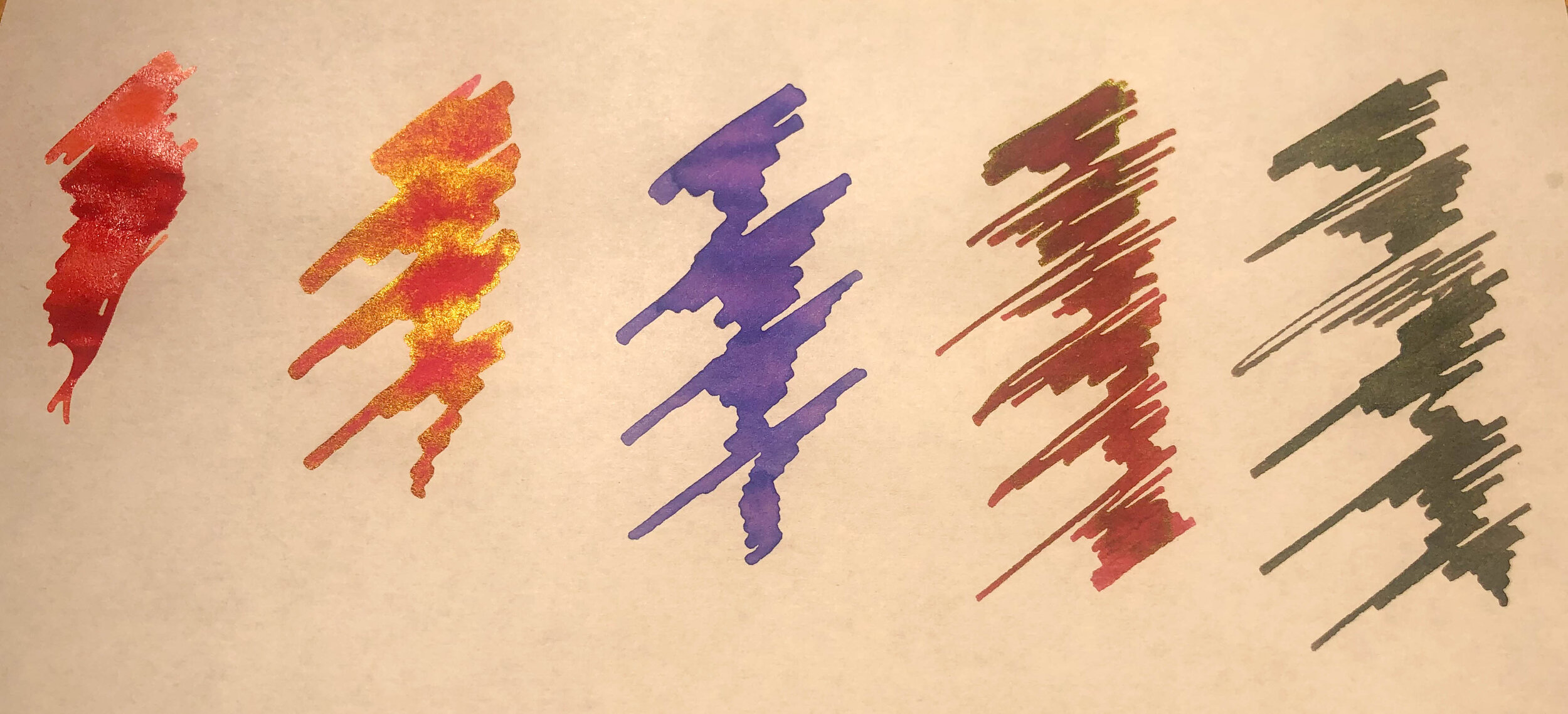

Not every ink will sheen, however, a large concentration of dye in ink, a large pool of ink + none absorbent paper is pretty much required to achieve a sheening result. How ever, in general, Certain sheen color tends to go with a certain color of ink. Red ink tends to sheen yellow/gold Blue ink tends to sheen red Purple ink tend to sheen green/yellow.

User can also promote sheening by leaving an ink unused in pen for a certain period of time. This will evaporate the water and makes ink even more concentrated.

(See first picture of the article to see examples of sheening. Mainly on the red colors)

Shimmer:

Different from sheening ink, the changing ink color is due to micro metallic particle in the ink.

These extra particles mixed in the ink will eventually sink to the bottom of the ink bottle if left undisturbed too long. Once they are loaded in a fountain pen, they will also settle down to the bottom part of the ink well or dry up in the nib unit.

While shimmering inks are fun to play with, make sure they are used up and do not allow it to dry up in pen.

Dried shimmering inks, while not impossible, is certainly a pain to clean. Also note, shimmering and sheening in ink are not mutually exclusive.

A notable ink is J.herban Emerald of Chivar. A green, beautiful ink that sheen red, but also with gold shimmer added.